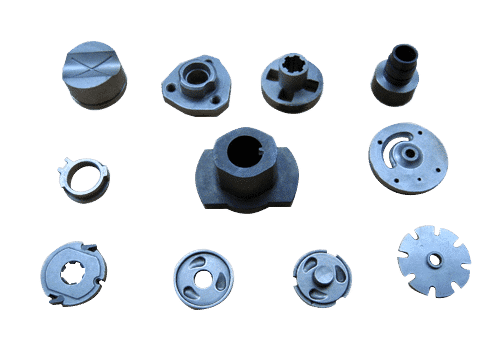

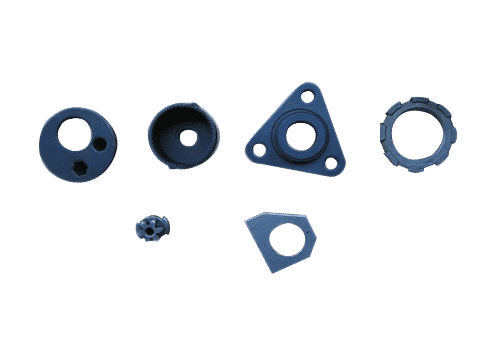

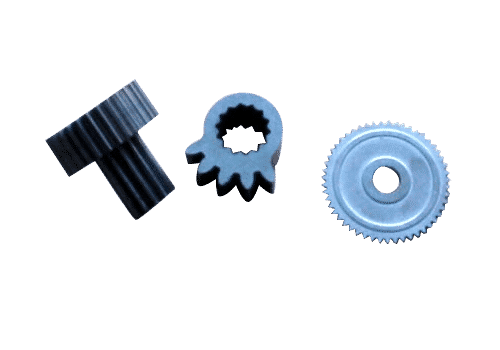

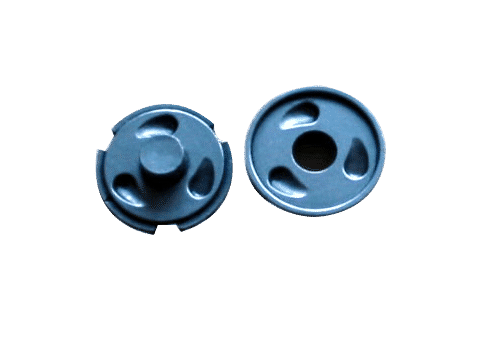

Powdered Metal Parts Manufacturing

Powdered metal manufacturing, as the name implies, is the fabrication of parts and components from metal that has been reduced to a powdered form. Powdered metal parts can be composed of a wide variety of materials, including aluminum, bronze, brass, steel, and stainless steel. The base metals are initially rendered into powder form through the use of physical force, chemical treatments, or electrolysis, depending on the material.

Once in powdered form, the metals are heat-treated and mixed with various elements to make them more amenable to the subsequent manufacturing processes. During the fabrication process, the powdered metal is compressed into the desired component shape and then hardened using a heat treating process called sintering. The precision, tolerance, and flexibility of powdered metal materials makes them useful for fabricating components for many industries, including construction, architecture, hardware, electronics, and automotive.

Advantages of Powdered Metal Parts

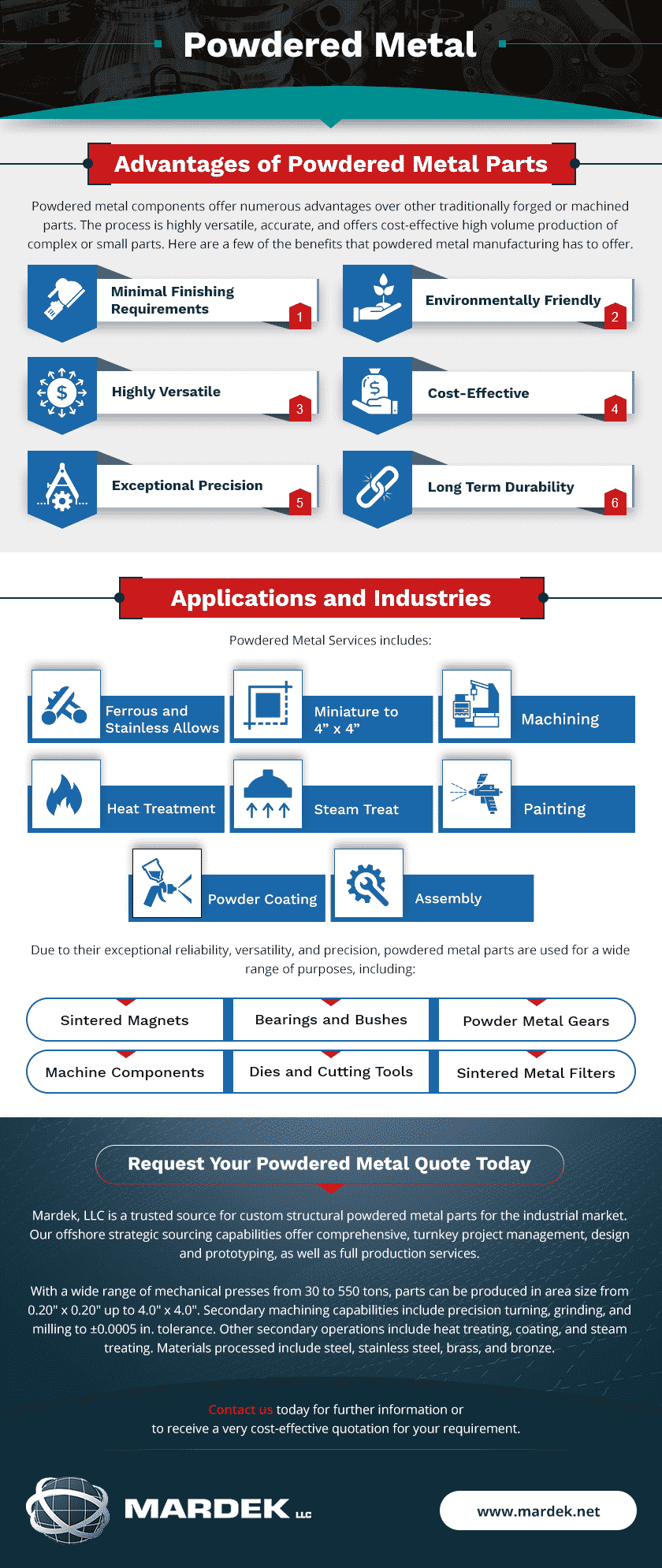

Powdered metal components offer numerous advantages over other traditionally forged or machined parts. The process is highly versatile, accurate, and offers cost-effective high volume production of complex or small parts. Here are a few of the benefits that powdered metal manufacturing has to offer.

Minimal Finishing Requirements

The powdered metal manufacturing process creates components with a smooth surface finish, with precise features. The net shape capabilities of the powdered metal process allow for the creation of superior components with minimal secondary machining or finishing.

Environmentally Friendly

Due to the reduced amount of energy needed to achieve finished components, the powdered metal process is often referred to as a green technology. Minimal waste and reduced energy usage give this process a much lower footprint than more traditional metal manufacturing processes.

Highly Versatile

Powdered metal manufacturing can be used to create parts in a wide range of shapes and sizes, using a variety of materials, including stainless steel, steel, bronze, brass, and aluminum, among many others.

Cost-Effective

Powdered metal processes are capable of high-volume production of unusual or particularly complex shapes with exceptional efficiency and low overhead. Fewer finishing requirements, reduced waste, and automation all contribute to the low cost of powdered metal manufacturing.

Exceptional Precision

Powdered metal components exhibit superior part-to-part consistency within exacting tolerances. The process is capable of producing highly detailed and complex parts with reliable precision.

Long Term Durability

Powdered metal manufacturing produces parts that can be relied upon for dependable long-term performance in critical applications. The manufacturing process allows for strong material composition, thereby enhancing the lifetime of the component and improving overall system performance, even in particularly harsh operating environments.

Applications and Industries

Powdered Metal Services includes:

- Ferrous and Stainless Allows

- Miniature to 4″ x 4″

- Machining

- Heat Treatment

- Steam Treat

- Painting

- Powder Coating

- Assembly

Due to their exceptional reliability, versatility, and precision, powdered metal parts are used for a wide range of purposes, including:

- Sintered magnets

- Bearings and bushes

- Powder metal gears

- Machine components

- Dies and cutting tools

- Sintered metal filters

Expert Powdered Metal Capabilities

With over 15 years of experience serving a broad range of industries, the team at Mardek has honed our powdered metal manufacturing capabilities to a science. Our facilities feature a fleet of mechanical presses ranging from 30 to 550 tons, which allows us to produce parts from 0.20 by 0.20 inches up to 4 by 4 inches with exceptional precision and efficiency.

Although our powdered metal components are produced with a smooth finish and high degree of accuracy, we are pleased to provide secondary machining services for those parts that need additional fine tuning. Our portfolio of secondary services includes precision turning, grinding, and milling within a tolerance of ±0.0005 inches. We are also pleased to offer a variety of finishing services to ensure that our powdered metal components meet the specific needs of any applications. Our finishing services include heat treating, coating, steam treating, painting, and assembly.

Request Your Powdered Metal Parts Quote Today

Mardek, LLC is a trusted source for custom structural powdered metal parts for the industrial market. Our domestic and offshore strategic sourcing capabilities offer comprehensive, turnkey project management, design and prototyping, as well as full production services. In addition to the our variety of manufacturing capabilities allows us to meet the most challenging design requirements. Contact us today if you are looking for an experienced offshore powdered metal manufacturer that you count on for consistent quality and delivery. We stand behind everything we manufacture and guarantee every product or part to your exact specifications every time.

With a wide range of mechanical presses from 30 to 550 tons, parts can be produced in area size from 0.20″ x 0.20″ up to 4.0″ x 4.0″. Secondary machining capabilities include precision turning, grinding, and milling to ±0.0005 in. tolerance. Other secondary operations include heat treating, coating, and steam treating. Materials processed include steel, stainless steel, brass, and bronze.

Contact us today for further information or to receive a very cost-effective quotation for your requirement.

Offshore Manufacturing Services

Mardek is a supplier of contract offshore manufacturing services in metal and plastic processes. We can help with you find the right solution for your contract metal fabrication, metal casting, plastics manufacturing components, assemblies, and even complete products.