We Make Offshore Local

Offshore Manufacturing Services

Mardek is a supplier of contract offshore manufacturing services in metal and plastic processes. We can help with you find the right solution for your contract metal fabrication, metal casting, plastics manufacturing components, assemblies, and even complete products.

Die Casting

At Mardek, we take advantage of the precision and quality die casting offers while optimizing the results with expert engineering and quality control.

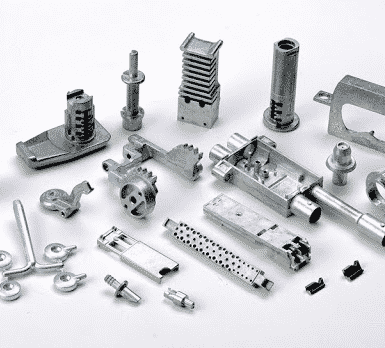

Metal Injection Molding

Mardek uses state-of-the-art metal injection molding technology to create high performing precision metal components to almost any level of complexity and volume.

Metal Casting

With unprecedented access to factories, raw material, knowledge, and expert personnel, Mardek, LLC guarantees on-time delivery of superior components to all of our clients.

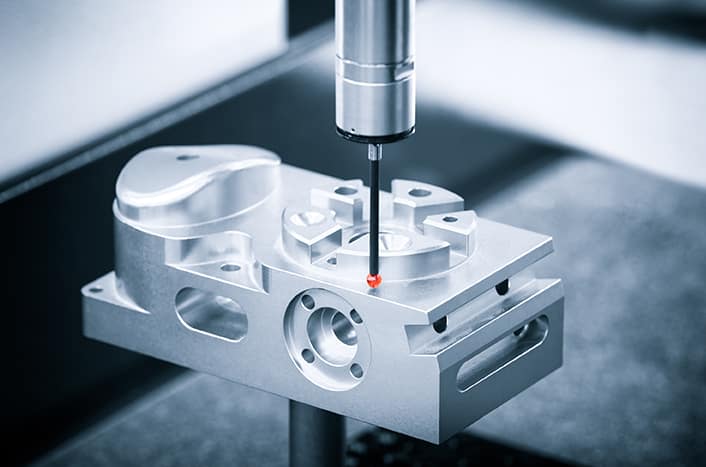

Quality

At Mardek, we take quality assurance very seriously, inspecting throughout the manufacturing process. We have also developed a highly reliable network of partner factories over the past 15 years that support these same values.

Mardek’s network of suppliers has the quality certifications needed to meet our customer requirements

ISO-9001

ISO/TS-16949

IATF-16949

Supply Chain Management

We Take Care of Everything

At Mardek, we specialize in cost-effectively providing custom manufactured parts, assemblies, and products through comprehensive management of manufacturing, shipping, and customs clearance.

Vendor searches and qualification

Supervise test runs

Manage costs

Handle international duties and customs

Evaluate & Explain Product specs

Negotiate prices

Eliminate language barriers

Overseas delivery

- Cost Effective

- Reliable

- Customer Focused

- Transparent

- Expert Team

Resources

Blog

- Metal Injection Molding ProcessMetal injection molding (MIM) merges the technology of plastic injection molding with powdered metallurgy. The process produces high volumes of small metal components with fine details and thin walls, allowing for greater design flexibility compared to die casting. The metal injection molding process provides an economical choice for manufacturing high volumes of complex parts in

- Which Metal Casting Method Is Right for You?Metal casting involves the process of pouring molten metal into a mold, and offers a simple and more affordable option when compared to subtractive manufacturing. The five basic steps of metal casting include

- The Benefits of Contract Manufacturers for Metal ManufacturingControlling production costs is crucial for being a competitive business, and our offshore contract metal manufacturing solutions are an excellent solution to provide superior quality and expertise while keeping costs low.

- A Closer Look at the Metal Casting ProcessMetal casting is a fabrication process that involves flowing molten metal into a custom-designed mold that contains a negative impression of the desired part or product.

- A Closer Look At Plastic ManufacturingMetal casting involves the process of pouring molten metal into a mold, and offers a simple and more affordable option when compared to subtractive manufacturing. The five basic steps of metal casting include

- The Benefits of Plastic Injection MoldingPlastic injection molding allows manufacturers to produce large quantities of plastic parts in a fast, efficient, and cost-effective manner. This process injects molten plastic into stiff molds or frames