Assembly Services

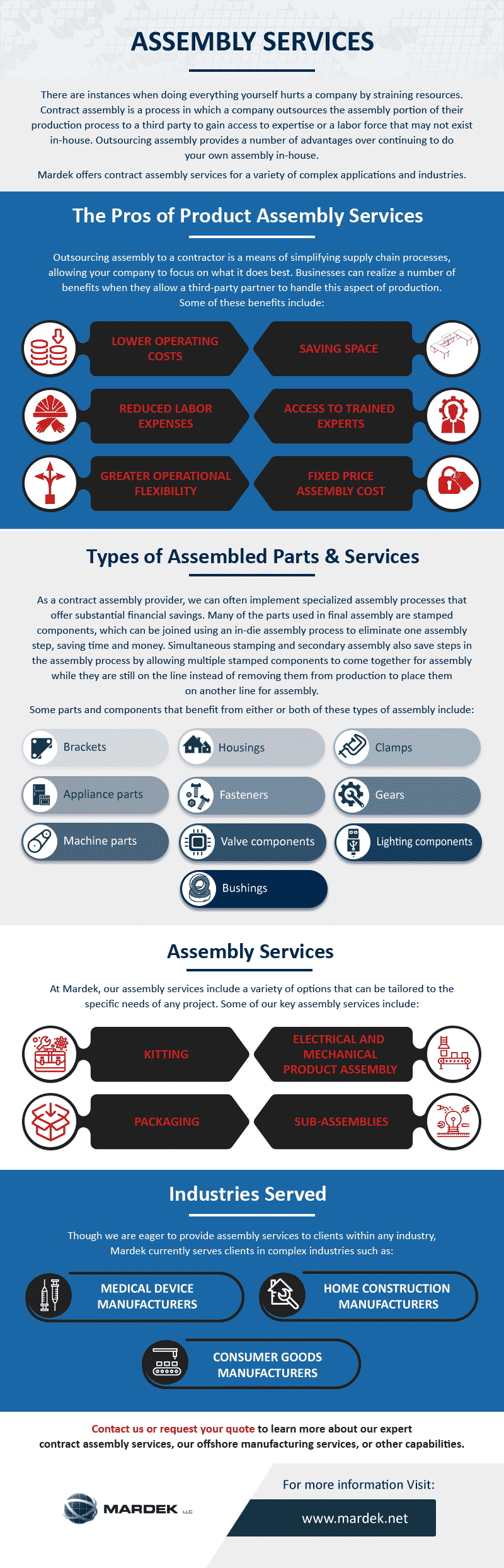

There are instances when doing everything yourself hurts a company by straining resources. Contract assembly is a process in which a company outsources the assembly portion of their production process to a third party to gain access to expertise or a labor force that may not exist in-house. Outsourcing assembly provides a number of advantages over continuing to do your own assembly in-house.

Mardek offers contract assembly services for a variety of complex applications and industries.

The Pros of Product Assembly Services

Outsourcing assembly to a contractor is a means of simplifying supply chain processes, allowing your company to focus on what it does best. Businesses can realize a number of benefits when they allow a third-party partner to handle this aspect of production. Some of these benefits include:

Lower Operating Costs

Assembly operating costs include investing in upgraded equipment, equipment maintenance, and salaries for specialized assembly personnel. Hiring a third party to handle assembly for your company allows you to significantly reduce the financial burden associated with assembly processes.

Saving Space

When space becomes tight within your facilities, it forces a business to make difficult decisions such as expansion, which costs even more money in land purchase and construction or leasing—or worse, rejecting new business because the operation doesn’t have the capacity. Outsourcing assembly processes offers a viable means to recover facility space that can then be repurposed to support growth.

Reduced Labor Expenses

Assembly personnel provide an entirely different service than other manufacturing employees. In-house assembly requires a specialized workforce and the associated salaries, benefits, and training that go with it. Contract assembly eliminates the need for additional labor and associated expenses.

Access to Trained Experts

Assembly may require a variety of specialized equipment and the expertise to operate it. Hiring a third party allows your company access to skilled personnel who can expertly operate a variety of specialized assembly tools, machinery, and packaging equipment.

Greater Operational Flexibility

Assembly set-ups must be tailored to the project. Outsourcing assembly skips this obstacle by allowing providers to make these adjustments between projects quickly, mitigating the hassle of managing intensive operational reconfigurations in-house.

Fixed Price Assembly Cost

The variable costs of assembly can be difficult to predict. Rather than allowing circumstances to effect assembly costs, contract assembly turns variable costs into a single fixed cost, allowing for tighter control of production budgets.

Types of Assembled Parts & Services

As a contract assembly provider, we can often implement specialized assembly processes that offer substantial financial savings. Many of the parts used in final assembly are stamped components, which can be joined using an in-die assembly process to eliminate one assembly step, saving time and money. Simultaneous stamping and secondary assembly also save steps in the assembly process by allowing multiple stamped components to come together for assembly while they are still on the line instead of removing them from production to place them on another line for assembly.

As a contract assembly provider, we can often implement specialized assembly processes that offer substantial financial savings. Many of the parts used in final assembly are stamped components, which can be joined using an in-die assembly process to eliminate one assembly step, saving time and money. Simultaneous stamping and secondary assembly also save steps in the assembly process by allowing multiple stamped components to come together for assembly while they are still on the line instead of removing them from production to place them on another line for assembly.

Some parts and components that benefit from either or both of these types of assembly include:

- Brackets

- Housings

- Clamps

- Appliance parts

- Fasteners

- Gears

- Machine parts

- Valve components

- Lighting components

- Bushings

Assembly Services

At Mardek, our assembly services include a variety of options that can be tailored to the specific needs of any project. Some of our key assembly services include:

Kitting

In the kitting process, components are produced simultaneously and then grouped for final assembly at your location or by your customers. This assembly process ensures that all the necessary components are present within the kit, and that each component is the specified type, size, and color to properly complete the finished assembly. Kitting saves the sorting and compiling steps of assembly.

Electrical and Mechanical Product Assembly

Many of the components used in electrical and mechanical products are stamped. Consequently, assembling these parts while they are still on the line saves time. Additionally, electrical and mechanical products require specialized assembly and specialized training to ensure optimal performance. Using this assembly process allows you to take advantage of top-level expertise without the need to source and hire skilled staff in-house.

Packaging

This is an important part of protecting your parts or assemblies during shipping. Packaging facilitates warehousing, inventory management, store displays, safe transport, and much more depending on the needs of the client.

Sub-Assemblies

Similar to electrical/mechanical assembly, sub-assemblies include activities that assemble various individual components into a single assembly for later inclusion as a unit in final assembly. Sub-assemblies often require specialized assembly processes, personnel, or equipment not available to the client.

Secondary Operations

Mardek also has the capacity to provide secondary operations to facilitate our assembly or yours, including:

- Cutting

- Machining

- Welding

Industries Served

Though we are eager to provide assembly services to clients within any industry, Mardek currently serves clients in complex industries such as:

- Medical device manufacturers. This includes assembly of electrical/mechanical equipment, as well as assembly of stamped or molded metal and plastic components.

- Home construction manufacturers. We produce assemblies used in home construction, including items like windows, door handles, and latches.

- Consumer goods manufacturers. Our services in this area include a broad range of activities that might include all aspects of assembly from kitting to electrical/mechanical assembly or sub-assemblies and packaging.

Assembly Support From Mardek

Limited resources require companies to make some hard decisions about which operations provide cost-effective solutions and which ones are hurting their bottom line. By outsourcing full or partial assembly to Mardek, you can cut operation costs, save space, reduce labor costs, increase operational flexibility, convert variable costs to fixed costs, and capitalize on our extensive assembly expertise.

Contact us or request your quote to learn more about our expert contract assembly services, our offshore manufacturing services, or other capabilities.

Offshore Manufacturing Services

Mardek is a supplier of contract offshore manufacturing services in metal and plastic processes. We can help with you find the right solution for your contract metal fabrication, metal casting, plastics manufacturing components, assemblies, and even complete products.