What Is Metal Injection Molding?

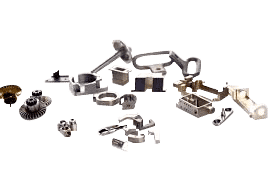

Metal injection molding (MIM) merges the technology of plastic injection molding with powdered metallurgy. The process produces high volumes of small metal components with fine details and thin walls, allowing for greater design flexibility compared to die casting.

The metal injection molding process provides an economical choice for manufacturing high volumes of complex parts in less time. It overcomes the difficulties of machining metals like nickel iron, stainless steel, and titanium. It also produces less scrap with a shorter turn-around.

Here at Mardek, LLC we offer various manufacturing services with capabilities in metal injection molding. Our process allows us to produce highly detailed complex metal components more efficiently and economically than could be accomplished using traditional manufacturing methods. Our goal is to bring innovation to manufacturing, and we continue to push the limits of our capabilities to support customers’ needs.

What is Metal Injection Molding?

Metal injection molding combines powdered metals with a polymer binder material to create metal parts. After the injection mold metal is melted, molded, and cooled, unwanted polymer material is eliminated by applying high heat to reveal a highly dense metal part. Recent process improvements now allow MIM to incorporate a wide variety of ferrous and non-ferrous alloys to produce non-corrosive metal parts with excellent strength and hardness properties.

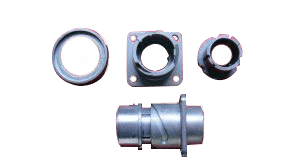

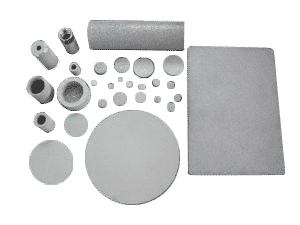

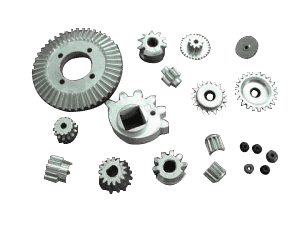

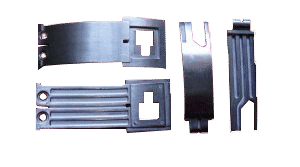

The metal injection molding process can produce a near-unlimited variety of shapes and geometries

- Preparing feedstock. Operators combine thermoplastic binder and metal powder to create feedstock, which is fed into the injection molding machinery. The feedstock is typically granulated for faster melting and efficient blending.

- Injection molding. The feedstock is injected into the mold to form a physical metal component in a plasticized state. The automated process can fill multiple mold cavities and reduce product flaws and imperfections. At this stage, the green product is approximately 20% larger than the final component. After cooling, the product gets ejected from the mold.

- Binder removal. At this stage, the intermediate binding material is thermally removed as the first step in the sintering process. The product is held at a specified temperature while the thermoplastic binding material evaporates through the pores of the component. The interconnected pore network is pre-engineered into the design to allow the plastic material to weep from the metal.

- Sintering. The final stage of the metal injection molding process ramps up the furnace temperature to sinter or compact the metal powder particles, eliminating the pore volume left behind from the elimination of the plastic binding material. Product shrinkage at this stage is offset by the higher initial product volume. Further surface finishing or heat-treating processes can now achieve the final specifications for hardness, ductility, and other mechanical or physical properties.

The MIM Process

There are four key steps in the metal injection molding process. The first is feedstock, where thermoplastic, wax binders, and fine metal powders are compounded to create a pelletized feedstock. These ultra-dense pellets ensure manufacturers can reach close tolerances when it comes to small and complex parts.

The next steps in the process are:

- Molding

- Feedstock is injected into the mold cavity after being heated

- The molded component that is created is identical to the finished piece, but is roughly 20% larger to allow for shrinkage

- Debinding

- Binders are removed to prepare for the final step

- Sintering

- The part is fragile and held together by a minimal amount of binder

- Sintering subjects the part to temperatures near the part material’s melting point

- Sintering offers parts their final strength and geometry

The Benefits of the MIM Process

Metal injection molding offers numerous benefits over traditional machining and metalworking processes:

- It is possible to manufacture high volumes of complex parts in less time with less scrap.

- The singular production process saves on floor space, manpower, and material costs.

- Powdered metals are equivalent to wrought alloys and exhibit superior mechanical properties compared to cast components.

- Available master alloys and pre-alloys facilitate variable mechanical strength, hardness, ductility, magnetization, corrosion-resistance, and more.

- Minimal finishing operations are required due to the inherent nature of injection molding.

- Reduced production time compared with casting.

- The de-binding and sintering stages of the molding process removes the binder material and also conditions the metal.

- Reduced production time compared with casting

- Superior mechanical properties of finished components

- Minimum secondary finishing operations required

- Tolerances as close as +/- 0.001

Metal Injection Molding Applications

MIM manufacturing has applications in industries requiring small components that would be difficult or expensive to machine, stamp, or die-cast. Some of the ideal scenarios for MIM manufacturing include:

- Medical devices. The process has extremely high repeatability, making it an excellent choice for FDA-approved medical devices.

- Aerospace. The aerospace industry benefits from the high precision and complex geometries produced by metal injection molding, with typical tolerances exceeding 0.5% on production runs of 100,000 components.

- Orthodontics. The one-off, custom design of orthodontic appliances is made affordable because of metal injection molding.

- Electronics. MIM facilitates the cost-effective miniaturization of electronic components for millions of consumer products.

- Consumer goods. Metal injection molded components can be found in a wide range of modern consumer domestic products like appliances, recreation equipment, watches, and jewelry.

- Industrial. Industrial applications for metal injection molding include parts for automotive engines and transmissions and military-grade firearm and munition components.

Learn More From Our Team of Metal Manufacturing Experts

Metal injection molding is a critical process in an array of industrial applications. It’s a cost-effective means of producing components with superior mechanical properties and excellent surface finishes. Your organization should strive to work with the right manufacturing company, so your metal injection-molded components retain their use and quality for many years.

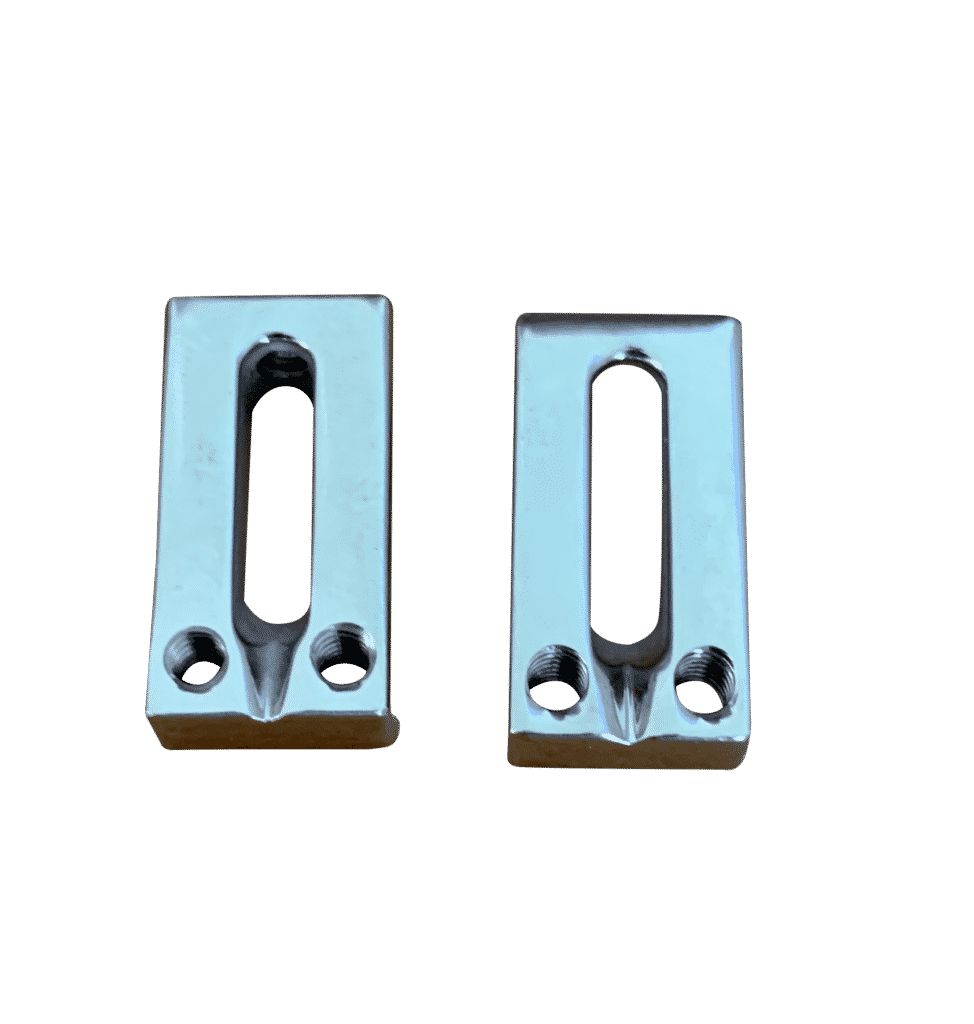

Our metal injection molding services include:

- Miniature to small complex net shapes

- Secondary machining

- Polishing

- Plating

We offer a number of value-added services, like die casting, metal stamping, and plastic manufacturing. No matter your industry or project size, our experienced staff is excited to discuss your upcoming project. Together, we’ll craft innovative solutions to drive your brand forward and increase profitability.

If you’re looking for that perfect partner, get in touch with the Mardek team today!

Offshore Manufacturing Services

Mardek is a supplier of contract offshore manufacturing services in metal and plastic processes. We can help with you find the right solution for your contract metal fabrication, metal casting, plastics manufacturing components, assemblies, and even complete products.