At Mardek, LLC., we take pride in being industry leaders in plastic manufacturing and machining. With our wide array of plastic manufacturing services, we produce parts ranging from miniature precision elements to large structural components. We provide secondary operations including inserts, hot stamping, labels, painting, plating, and assembly.

Our team uses a wide variety of plastic materials including commodity type plastics typically used in consumer goods and food packaging, as well as in engineering-grade materials for applications that require more strength, durability, and tolerance to demanding service environments.

Our areas of expertise in plastic manufacturing include:

- Injection molding and secondary operations

- Thermoforming and vacuum forming

- Blow molding

- Extrusions

- Machining and assembly

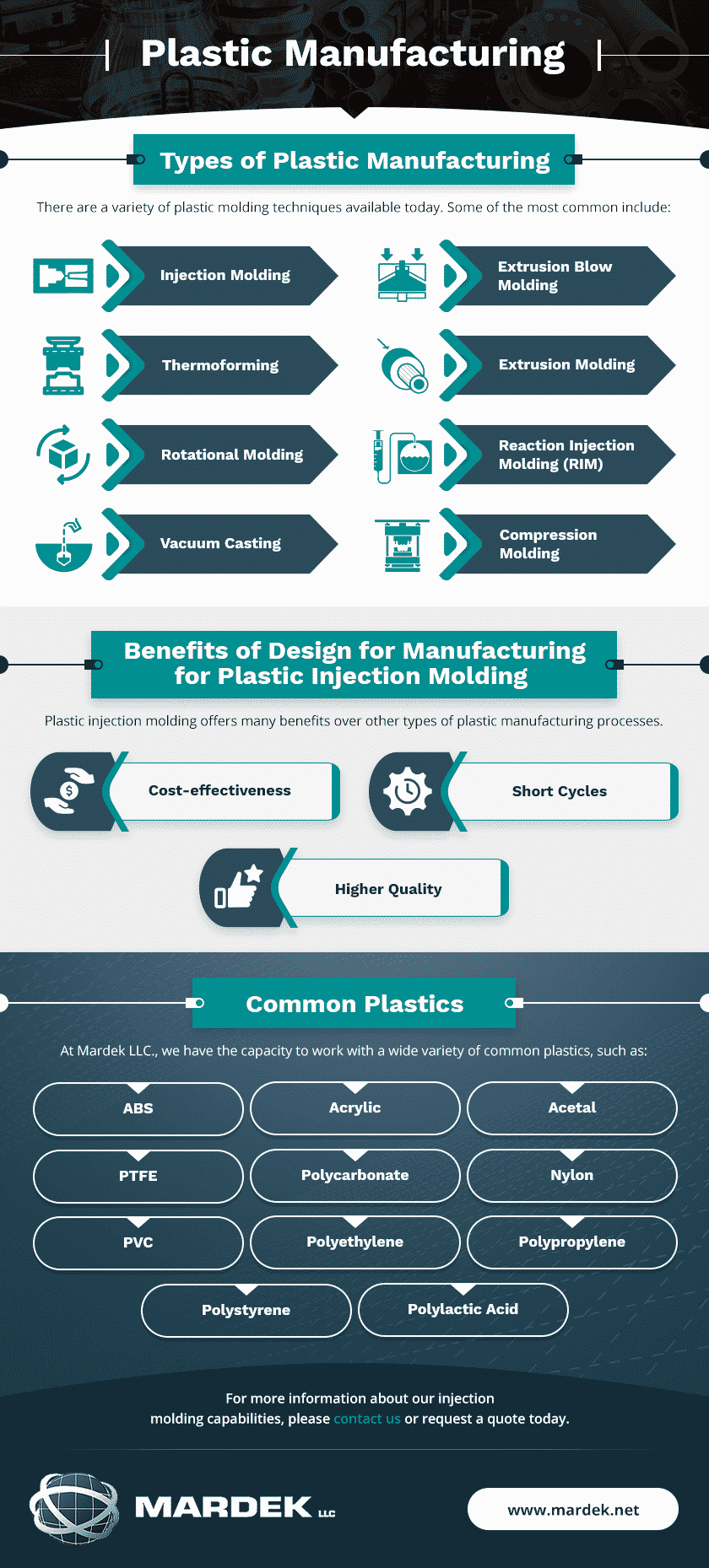

Types of Plastic Manufacturing

There are a variety of plastic molding techniques available today. Some of the most common include:

Injection Molding

Injection molding is the most common method used for the mass production of plastic parts due to its versatility. This process forces melted plastic resin pellets into a metal mold where it is cooled before being ejected from the mold as a solid plastic part. Injection molding machines can manufacture large components, such as automobile parts and precision plastic parts used in medical and surgical applications. This type of plastic manufacturing often depends on thermoplastics which can be melted and cooled multiple times, thereby limiting waste through reuse.

Extrusion Blow Molding

To produce inexpensive thin-walled products such as single-use drinking cups or bottles, manufacturers use extrusion blow molding. This fast process requires easy-to-make tools and is capable of generating complex precision components. Several variations of the blow molding process exist, but in general the process requires the production of a parison, or pre-shaped and hollow length of melted thermoplastic. After a mold closes around this object, air pressure forces its way into the hollow parison, expanding it to fit the mold and leaving a cavity in the interior of the produced plastic.

Thermoforming

Using vacuum pressure, a manufacturing process called thermoforming molds a thin gauge plastic sheet into its final shape. After applying heat, the sheet of plastic stretches over the die surface while the vacuum pressure pulls it into the desired shape. The process can be performed with simple dies and basic equipment, and often sees use in the creation of samples and prototypes of thin-walled, hollow-bodied parts, as well as plastic cups, lids, plastic clamshell packaging, and more.

Extrusion Molding

During extrusion molding, melted plastic is extruded or forced out directly through a die with a fixed cross shape. There is no mold required since the die shape determines the final shape of the component. Extrusion molding offers an efficient method for manufacturing plastic parts in a variety of profiles. The extrusion molding process is used primarily with thermoplastics.

Rotational Molding

Rotational molding is a plastic manufacturing process used to produce large hollow components. After placing a powder or liquid resin into the mold, the mold is rotated in an oven. Then, centrifugal force causes the resin to coat the inside of the mold evenly. The process results in an even-walled product which is cooled and hardened before being removed from the mold. This type of process is not as fast as some other plastic molding options, but it generates little waste and reuses excess material.

Reaction Injection Molding (RIM)

Commonly used in the automotive industry, Reaction Injection Molding (RIM) produces rigid, lightweight parts that are easily painted, such as body panels, dashboards, and other car parts. The thermoset plastics used in RIM undergo a chemical reaction inside the mold, causing them to expand inside the mold before hardening into the final product. Production costs for this type of molding can be moderately expensive because the resulting part must always be finished, generally with a urethane-based gel coat or painting, resulting in additional labor costs.

Vacuum Casting

Without a large investment in tools or materials, vacuum casting often sees use creating high-quality prototypes. A model of any rigid shape is placed into a sealed container, which is then filled with a flexible silicone. After removing the model, the cavity inside the mold can be filled with plastic to make a copy of the original. Vacuum pressure removes air from the mold to ensure that no bubbles are present and that the mold fills completely. While the molds lack durability and begin to degrade after a few uses, the finished product has excellent detail and a quality surface finish.

Compression Molding

The compression molding process works by heating plastic, pouring it into a heated mold, and compressing it into shape. Like other molding processes, the finished part is cooled to retain its shape before being removed from the mold. A popular process for the automotive industry, compression molding is well-suited for high-strength compounds like thermoset resins, fiberglass, and reinforced plastics.

Benefits of Design for Manufacturing for Plastic Injection Molding

Plastic injection molding offers many benefits over other types of plastic manufacturing processes. Some of these include:

- Cost-effectiveness. As a cost-efficient plastic manufacturing process, injection molding can lower overall production costs with a lower cost per part, minimal waste of raw materials, lower capital equipment costs, an emphasis on standards, and greater potential for automation to reduce labor expenses.

- Short cycles. The process enables production to be brought to capacity sooner, reducing the product development cycle and bringing the product to market sooner with fewer engineering changes.

- Higher quality. Injection molding offers superior repeatability and added complexity over many other plastic molding processes, ensuring high quality production.

Common Plastics

At Mardek LLC., we have the capacity to work with a wide variety of common plastics, such as:

- ABS

- Acrylic

- Acetal

- PTFE

- Polycarbonate

- Nylon

- PVC

- Polyethylene

- Polypropylene

- Polystyrene

- Polylactic acid

Why Choose Mardek’s Plastic Manufacturing Services

Mardek, LLC. is an industry leader in plastic manufacturing and machining. Our long-lasting relationships and ISO-9001-certified offshore, Asia-based manufacturing facilities guarantee the highest quality for everything we produce. These capabilities allow us to provide high-volume molded parts, as well as lower volume custom-cast or machined plastic parts to meet your budget. This is accomplished by our highly skilled staff and utilizing the latest plastic manufacturing equipment. Our logistics specialists will make sure your parts are delivered on-time and safely to your loading dock. Years of experience in plastics manufacturing allow us to transform your designs into finished parts that exceed your expectations.

For more information about our injection molding capabilities, please contact us or request a quote today.

Offshore Manufacturing Services

Mardek is a supplier of contract offshore manufacturing services in metal and plastic processes. We can help with you find the right solution for your contract metal fabrication, metal casting, plastics manufacturing components, assemblies, and even complete products.