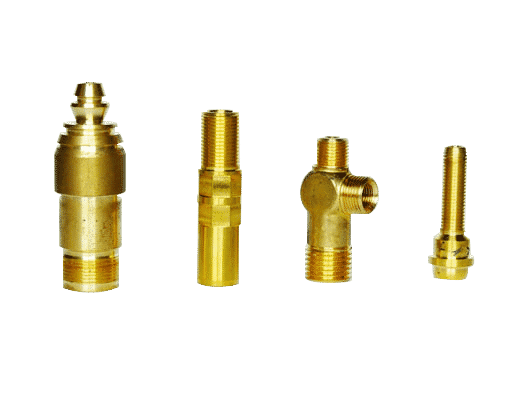

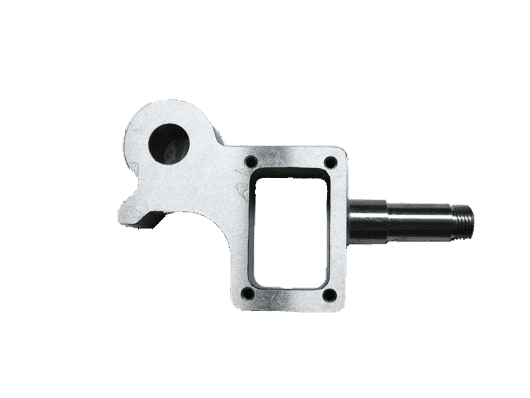

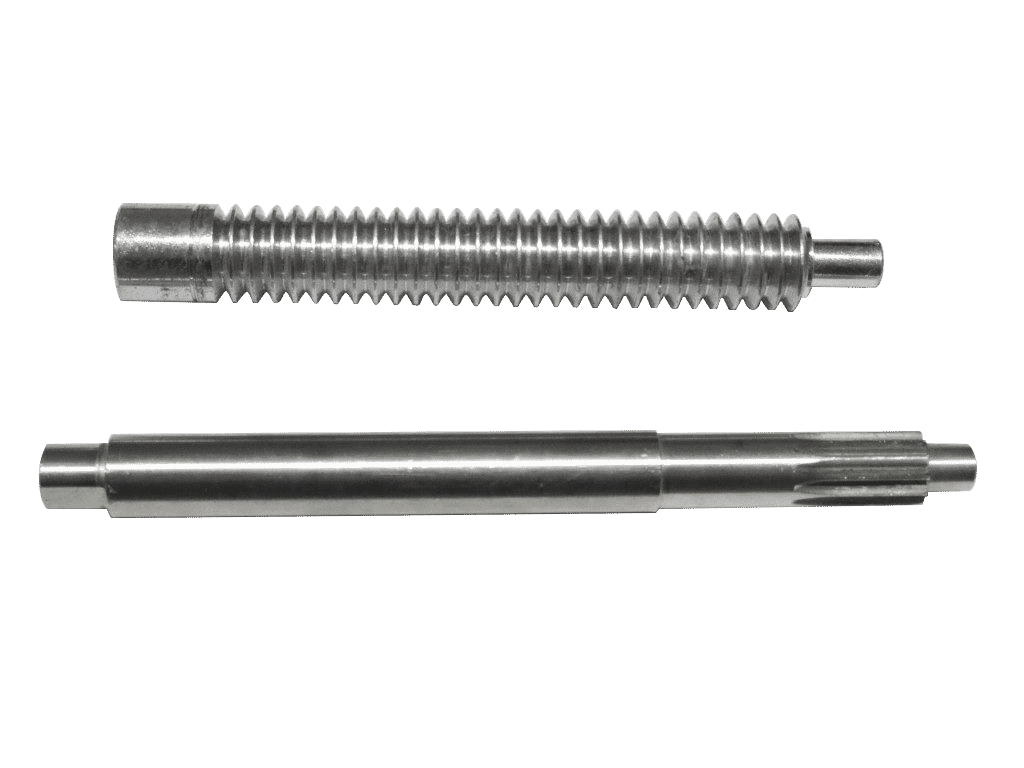

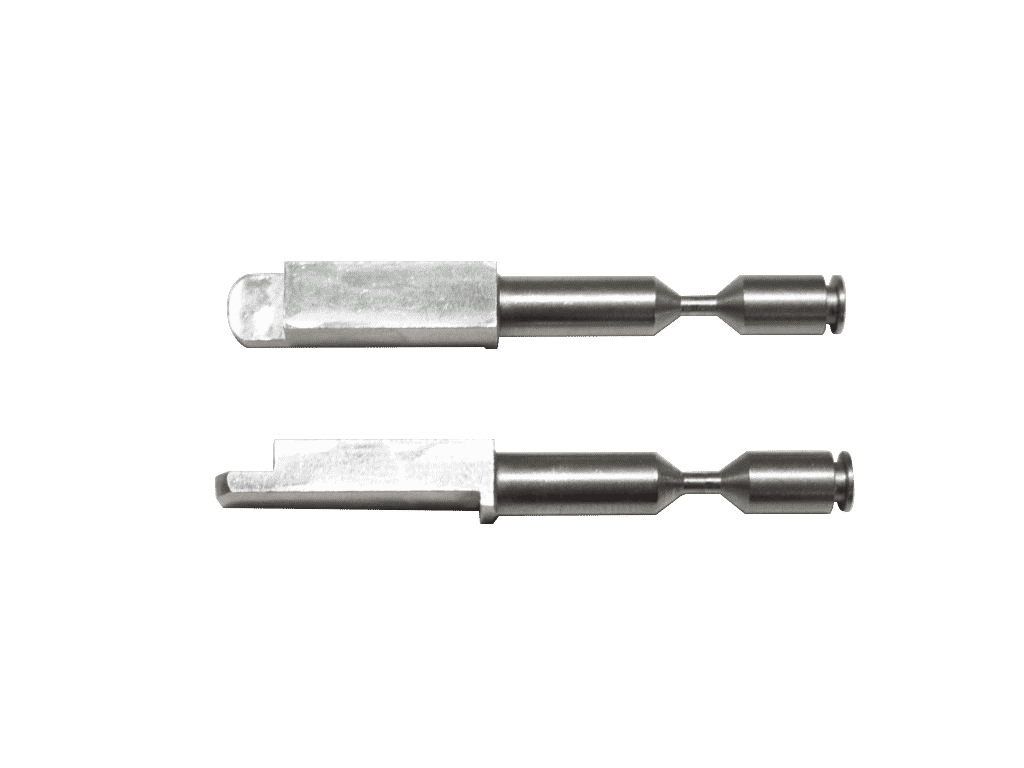

CNC Machining

Computer numerical control (CNC) machining is an umbrella term for the subtractive manufacturing processes that use computer software to direct the operation of tooling and equipment. CNC can be integrated into several types of machining equipment, ranging from lathes and mills to grinders and routers, to simplify and streamline the manufacturing process. The precision and efficiency afforded by CNC machining often eliminate the need for manual machining or additional processing operations.

As a leader in the offshore metal manufacturing industry, Mardek, LLC has the knowledge and tools necessary to supply precision machined metal and plastic components made to the highest quality standards and the most stringent specifications. Over the years, we have built numerous overseas business relationships with highly qualified and vetted manufacturers, which allows us to choose the perfect CNC technology for the part, precision, and production capabilities you need.