Offshore manufacturing is an essential part of cost-efficient production for many businesses. By offering an extensive network of available offshore facilities Mardek allows companies in the United States to reduce production and operation costs while providing quality products and fast production cycles. Mardek offers products and services for a wide range of applications and industries.

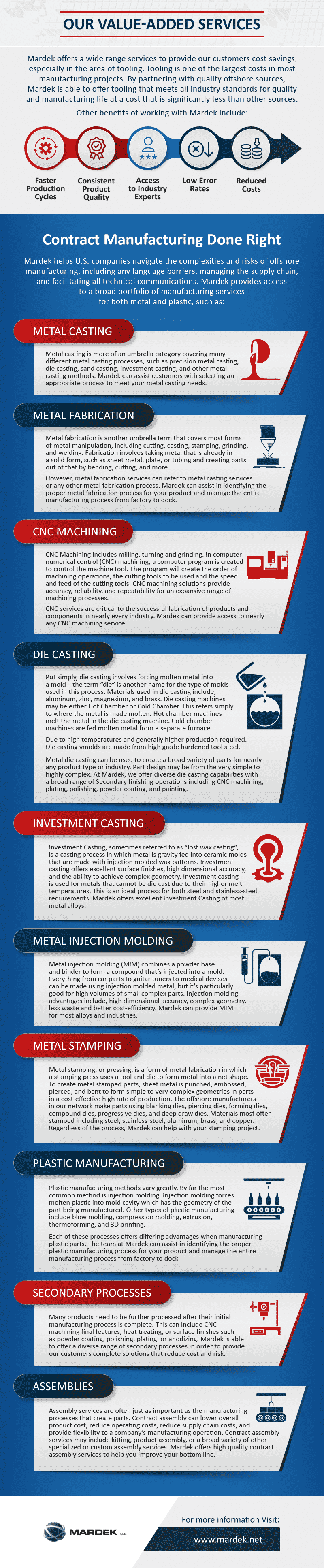

Mardek offers a wide range services to provide our customers cost savings, especially in the area of tooling. Tooling is one of the largest costs in most manufacturing projects. By partnering with quality offshore sources, Mardek is able to offer tooling that meets all industry standards for quality and manufacturing life at a cost that is significantly less than other sources.

Other benefits of working with Mardek include:

- Faster production cycles

- Consistent product quality

- Access to industry experts

- Low error rates

- Reduced costs

Contract Manufacturing Done Right

Mardek helps U.S. companies navigate the complexities and risks of offshore manufacturing, including any language barriers, managing the supply chain, and facilitating all technical communications. Mardek provides access to a broad portfolio of manufacturing services for both metal and plastic, such as:

Mardek helps U.S. companies navigate the complexities and risks of offshore manufacturing, including any language barriers, managing the supply chain, and facilitating all technical communications. Mardek provides access to a broad portfolio of manufacturing services for both metal and plastic, such as:

Metal Casting

Metal casting is more of an umbrella category covering many different metal casting processes, such as precision metal casting, die casting, sand casting, investment casting, and other metal casting methods. Mardek can assist customers with selecting an appropriate process to meet your metal casting needs.

Metal Fabrication

Metal fabrication is another umbrella term that covers most forms of metal manipulation, including cutting, casting, stamping, grinding, and welding. Fabrication involves taking metal that is already in a solid form, such as sheet metal, plate, or tubing and creating parts out of that by bending, cutting, and more.

However, metal fabrication services can refer to metal casting services or any other metal fabrication process. Mardek can assist in identifying the proper metal fabrication process for your product and manage the entire manufacturing process from factory to dock.

CNC Machining

CNC Machining includes milling, turning and grinding. In computer numerical control (CNC) machining, a computer program is created to control the machine tool. The program will create the order of machining operations, the cutting tools to be used and the speed and feed of the cutting tools. CNC machining solutions provide accuracy, reliability, and repeatability for an expansive range of machining processes.

CNC services are critical to the successful fabrication of products and components in nearly every industry. Mardek can provide access to nearly any CNC machining service.

Die Casting

Put simply, die casting involves forcing molten metal into a mold—the term “die” is another name for the type of molds used in this process. Materials used in die casting include, aluminum, zinc, magnesium, and brass. Die casting machines may be either Hot Chamber or Cold Chamber. This refers simply to where the metal is made molten. Hot chamber machines melt the metal in the die casting machine. Cold chamber machines are fed molten metal from a separate furnace.

Due to high temperatures and generally higher production required. Die casting molds are made from high grade hardened tool steel.

Metal die casting can be used to create a broad variety of parts for nearly any product type or industry. Part design may be from the very simple to highly complex. At Mardek, we offer diverse die casting capabilities with a broad range of Secondary finishing operations including CNC machining, plating, polishing, powder coating, and painting.

Investment Casting

Investment Casting, sometimes referred to as “lost wax casting”, is a casting process in which metal is gravity fed into ceramic molds that are made with injection molded wax patterns. Investment casting offers excellent surface finishes, high dimensional accuracy, and the ability to achieve complex geometry. Investment casting is used for metals that cannot be die cast due to their higher melt temperatures. This is an ideal process for both steel and stainless-steel requirements. Mardek offers excellent Investment Casting of most metal alloys.

Metal Injection Molding

Metal injection molding (MIM) combines a powder base and binder to form a compound that’s injected into a mold. Everything from car parts to guitar tuners to medical devises can be made using injection molded metal, but it’s particularly good for high volumes of small complex parts. Injection molding advantages include, high dimensional accuracy, complex geometry, less waste and better cost-efficiency. Mardek can provide MIM for most alloys and industries.

Metal Stamping

Metal stamping, or pressing, is a form of metal fabrication in which a stamping press uses a tool and die to form metal into a net shape. To create metal stamped parts, sheet metal is punched, embossed, pierced, and bent to form simple to very complex geometries in parts in a cost-effective high rate of production. The offshore manufacturers in our network make parts using blanking dies, piercing dies, forming dies, compound dies, progressive dies, and deep draw dies. Materials most often stamped including steel, stainless-steel, aluminum, brass, and copper. Regardless of the process, Mardek can help with your stamping project.

Plastic Manufacturing

Plastic manufacturing methods vary greatly. By far the most common method is injection molding. Injection molding forces molten plastic into mold cavity wich has the geometry of the part being manufactured. Other types of plastic manufacturing include blow molding, compression molding, extrusion, thermoforming, and 3D printing.

Each of these processes offers differing advantages when manufacturing plastic parts. The team at Mardek can assist in identifying the proper plastic manufacturing process for your product and manage the entire manufacturing process from factory to dock

Secondary Processes

Many products need to be further processed after their initial manufacturing process is complete. This can include CNC machining final features, heat treating, or surface finishes such as powder coating, polishing, plating, or anodizing. Mardek is able to offer a diverse range of secondary processes in order to provide our customers complete solutions that reduce cost and risk.

Assemblies

Assembly services are often just as important as the manufacturing processes that create parts. Contract assembly can lower overall product cost, reduce operating costs, reduce supply chain costs, and provide flexibility to a company’s manufacturing operation. Contract assembly services may include kitting, product assembly, or a broad variety of other specialized or custom assembly services. Mardek offers high quality contract assembly services to help you improve your bottom line.

Offshore Manufacturing with Mardek, LLC

Mardek offers plastic and metal manufacturing in offshore locations to help keep your costs under control. Combined with our ability to provide diverse Secondary Processes and Assembly Services Mardek offers our customers the ability to reduce unit prices, tooling cost, supply chain costs, and operations costs with increased flexibility without sacrificing quality, reliability, or schedule.

If you’d like to discuss our offshore manufacturing capabilities for your project, please contact us or request your quote.